Operational strength testing

To ensure that your products remain in function as long and safely as possible, the Automotive Technical Center offers you the possibilities for:

- Seat load tests,

- Impact, shock and shock tests,

- oscillation and vibration tests,

- tensile and compression tests,

- torsion tests,

- under- and overpressure tests.

When testing your products, we focus in particular on continuous loads, alternating loads as well as overloads and peak loads in accordance with the prescribed standard or your specifications.

In addition, we offer you the possibility of carrying out various combination tests in the ATB, such as oscillation, vibration and shock tests or movement, tension and pressure tests under climatized environmental conditions.

Real seat test

As a special feature, the Automotive Technical Center offers you the special opportunity to carry out real seat load and entry/exit tests.

KUKA OccuBot seat testing robot

The KUKA Occubots imitate human movements and loads with unparalleled precision. In doing so, the robots reproduce extremely realistic simulations of entry and exit procedures, turn-in tests or even backrest scuffing tests.

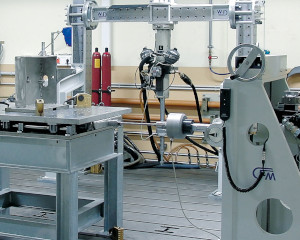

Linear cylinder test stands

We realize the experimental proof of the operational stability by the use of hydro-pulse, pneumatic and electric lifting cylinder test stands, thanks to which mechanical continuous and alternating loads can be transferred to the test specimen in a precise and force-dosed manner.

Electrodynamic shaker

Laboratory unit for shock load tests and vibration tests. Can be used in either horizontal or vertical axis. Operated with a vibration control system with sine, noise or shock signals.